Engineering

YY Mold's objective is to provide best service in DFM report, mold flow analysis, 3D&2D drawing for new production tooling or prototype tooling.

All designers have more than 10 yesrs experiences in exporting tooling design. They are able to read customer’s requirement in English and familiar with North American and European standard, like DME, HASCO, MEUSBURGER etc.

We use Unigraphic,Pro-E and Solidworks for our CAD software, which are 3D solid modeling and surfacing software, that has a mold design module that helps create complicated parting line splits.

Design Process

¨ Receive kick off Notice and Part Data& TDS from Project Manager.

¨ Attend official kick off meeting to verify whether all information is completed. It must be finished within 24 hours after receiving customer official kick off email.

¨ Create formal designer folder. All information are put into one folder that names by YYMOLD tooling number, like TDS, part 3D data and 2D drawing, customer standard, injection machine information, DFM report& customer’s comments, mold flow.

¨ DFM Report-(after kick off meeting, we will start to do DFM report. Generally, it takes 2-3 days after kick off meeting)

¨Submit DFM Report for Project Manager to review and translate. It must be done and summited to customer on that day of DFM report completion.

¨ Start Mold Structure design after receiving customer DFM report feedback. Generally, it will take 1-2 days.

¨ Design review with manufacture and project team after finish mold structure design.

¨ Start Preliminary Design. Generally, it takes 4-5 days.

¨ Start final design after receiving customer preliminary design feed back. Generally, it takes 3-4 days.

¨ BOM& Component Drawing.

The purpose is to clearly show you how we do efficient design job to help customer’s project earn more time. For general mold, it takes 2-3 weeks. More complex mold design timing depends on actual mold structure.

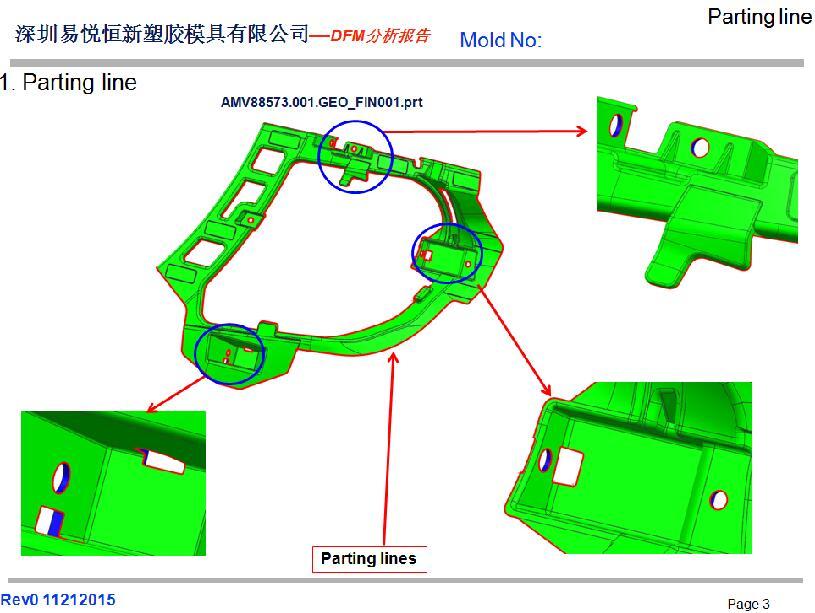

DFM Report

DFM Report

Includes below information:

¨ Key part&mold information (part size, material, shrinkage, surface requirement, mold steel, hot runner, cavitation)

¨ Part PL and Slide& lifter parting line.

¨ Insert & insert pin, gate type & location ejector pin, mold layout.

¨ Mention modification solution to part issue, de-moulding issue and mold structure issue.

¨ Partdraftanalysis & wall thickness analysis.

¨ Cavity &core surface finish

Our professionalism and understanding of plastic mold technology gives us the capacity to predict all issue and solve them during DFM report discussion.